I’m QiaoMei, with over 25+ years of expertise in OEM, ODM and private label cosmetics, focusing on crafting high-quality HairCare Skincare BodyCare and makeup products with unparalleled insights into formulation, quality and market trends

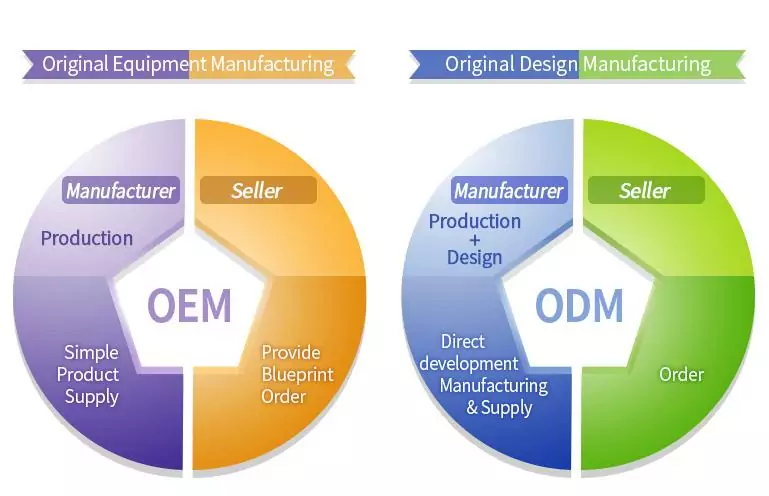

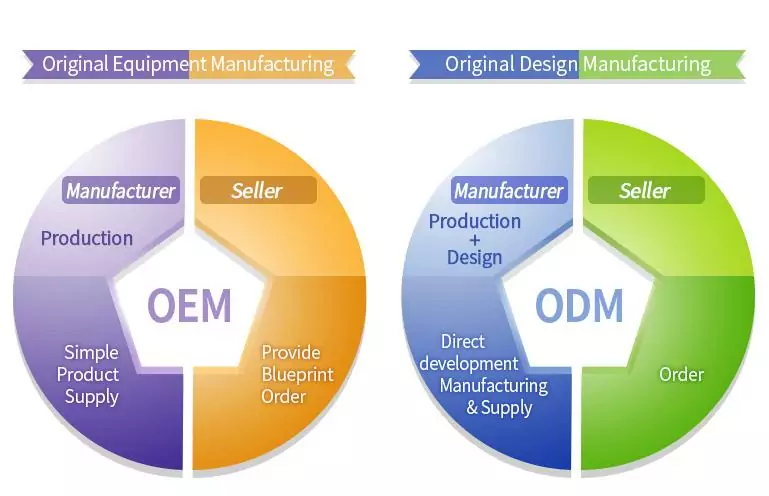

Manufacturers operate under various business models. In some cases, they produce goods that are entirely designed and manufactured in-house. In others, they manufacture products based on clients’ design specifications.

These different production approaches serve as key distinguishing factors, reflecting a company’s capabilities and scope of work. Typically, manufacturers are categorized into OEM and ODM .

OEM – Original Equipment Manufacturing // When a factory makes a product but customizes it based on a client’s design

ODM – Original Design Manufacturing // When a manufacturer designs and produces it in-house and sells it to a client with little to no modifications

The difference between OEM and ODM

OEM means a company designs and develops a product but often outsources manufacturing to a third-party company. The third-party manufacturer then creates the product under the brand name of the company that designed it. In other words, the company that developed the product doesn’t actually manufacture it itself. Instead, they focus on product design, marketing, and sales.

The ODM approach involves the manufacturer not only producing the items but also designing them from scratch. In this case, the manufacturer is responsible for the entire product development process, from design to production. The company that hires the ODM manufacturer will then sell the product under its own brand name.

To conclude, the main difference between OEM and ODM is that with OEM, the company that designed the product outsources the manufacturing, while with ODM, the manufacturer produces and designs the product.

The Advantages of Choosing OEM/ODM for Private Label Cosmetics

In today’s highly competitive beauty market, a growing number of entrepreneurs, influencers, distributors, and traditional businesses are embracing private label branding as a strategic transformation. Cosmetic OEM/ODM manufacturing has emerged as the most efficient pathway to rapidly turn brand visions into reality.

1. Low-Cost, Low-Risk Market Entry

Eliminate capital-intensive investments in facilities, equipment, and R&D teams (typically requiring millions). Benefit from minimum order quantities (MOQs) as low as 2,000 units for product testing, reducing inventory risks. Quickly reformulate or repackage products based on market feedback to minimize deadstock losses.

2. Professional R&D Support for Competitive Edge

Leverage manufacturers’ expert formulation teams offering:

- Custom active ingredients

- Proven formula libraries (whitening, anti-aging, repair solutions)

- Market intelligence on trending categories Ensures precise product positioning.

3. Rapid Production to Capture Market Opportunities

Traditional in-house development requires 6-12 months for R&D, testing, and regulatory filing—often missing trends. By adopting OEM/ODM manufacturers’ pre-developed formulas, achieve market-ready products in just 1-3 months.

4. Regulatory Compliance & Risk Mitigation

Top-tier manufacturers maintain:

- International certifications (ISO 22716, GMP)

- Complete documentation (COA, MSDS, stability reports)

- Proactive adaptation to regulatory changes (e.g., China NMPA filings)

Final Thoughts

Conclusion: Your Brand Acceleration Platform

• Startups: Begin with ODM to validate demand

• Established Brands: Transition to OEM for proprietary formulations

• Long-Term Strategy: Hybrid “ODM+OEM+In-House R&D” model balances speed and differentiation

Selecting the right manufacturing partner gives your brand wings to soar.

What to consider before choosing an OEM?

When selecting an OEM partner, it is imperative to thoroughly evaluate whether the company strictly adheres to international best practices and standards, such as ISO 22716 (Good Manufacturing Practices for Cosmetics) and ISO 9001.

Furthermore, you should assess whether the company maintains rigorous safety, reliability, and quality standards throughout its cosmetic/skincare manufacturing processes.

Products manufactured in a compliant environment that follows international ethical norms typically experience smoother export procedures across international markets.

Here are some other vital factors to consider before you choose an OEM:

1.A binding contract

When considering working with an OEM manufacturer, you should consult the services of a commercial lawyer. The contract you draw up should contain a confidentiality clause that states the limits and boundaries of both parties.

2.Best practices

Before the OEM begins the production of your cosmetic/skincare product, ensure to learn the standards your product should adhere to. Ideally, it would help if you had a checklist of everything you may want to check as you don’t want to run afoul of the law.

3.Active ingredients

When checking for an OEM, ensure to ask for the source of the ingredients. For instance, if you consider supplying the product to a Muslim area, you need to consider the Halal rule. Knowing the active ingredients and the same acceptability in your target market will help you make better-informed decisions.

4.Relevant samples

Have a chat with the producer and reach a compromise about how the product will smell, look, feel, and function. Ideally, you should request a sample and the package it will be in. Before placing the final order, look out for your cosmetic/skincare formulation’s color, texture, viscosity, and smell.

5.Delivery time and size

The final factor you should consider is the delivery method of the OEM cosmetic/skincare product. For instance, would you rather have your products made in batches? How much time would you want it to be delivered?

Qiaomei Cosmetic Manufacturing Advantage

How Can QiaoMei Cosmetics Elevate Your Brand or Business? Why Choose Us as Your OEM/Private Label Partner?

Rich Experience & Professional Expertise

With 25 years of experience in the beauty and skincare industry, QiaoMei Cosmetics operates an 80,000+ sqm GMPC-certified production base equipped with 16 fully automated production lines, ensuring large-scale order fulfillment. Our primary markets include China, Europe, the U.S., the Middle East, and Southeast Asia. Additionally, our in-house R&D team and design specialists guarantee high-quality formulations and innovative product development.

Low MOQ Support

Whether you’re a startup or an SME, minimum order quantities won’t be a barrier. QiaoMei Cosmetics offers orders as low as 1,000 units, providing customized solutions tailored to your needs.

Fast & Efficient Business Process

We streamline collaboration for a hassle-free experience:

- Submit your requirements via our website.

- Our dedicated sales consultant will promptly contact you with a quote and samples.

- Once approved, we’ll handle everything from packaging design to logistics, ensuring a seamless journey.

QiaoMei OEM Service Advantages

✔ Diverse Product Range

From skincare, haircare, to body care, we offer men’s, women’s, adult, children’s, and even pet-friendly cosmetics, covering all market demands.

✔ Custom Active Ingredients

Need specialized formulations? We can incorporate your desired ingredients (subject to safety approval by our engineers to meet international cosmetic standards).

✔ Dedicated After-Sales Support

Our commitment extends beyond delivery—we’re invested in your success. For any inquiries or support, our team is always ready to assist.

Choosing QiaoMei Cosmetics means partnering with a professional, efficient, and trustworthy ally for long-term growth. Let’s build your premium beauty brand together!